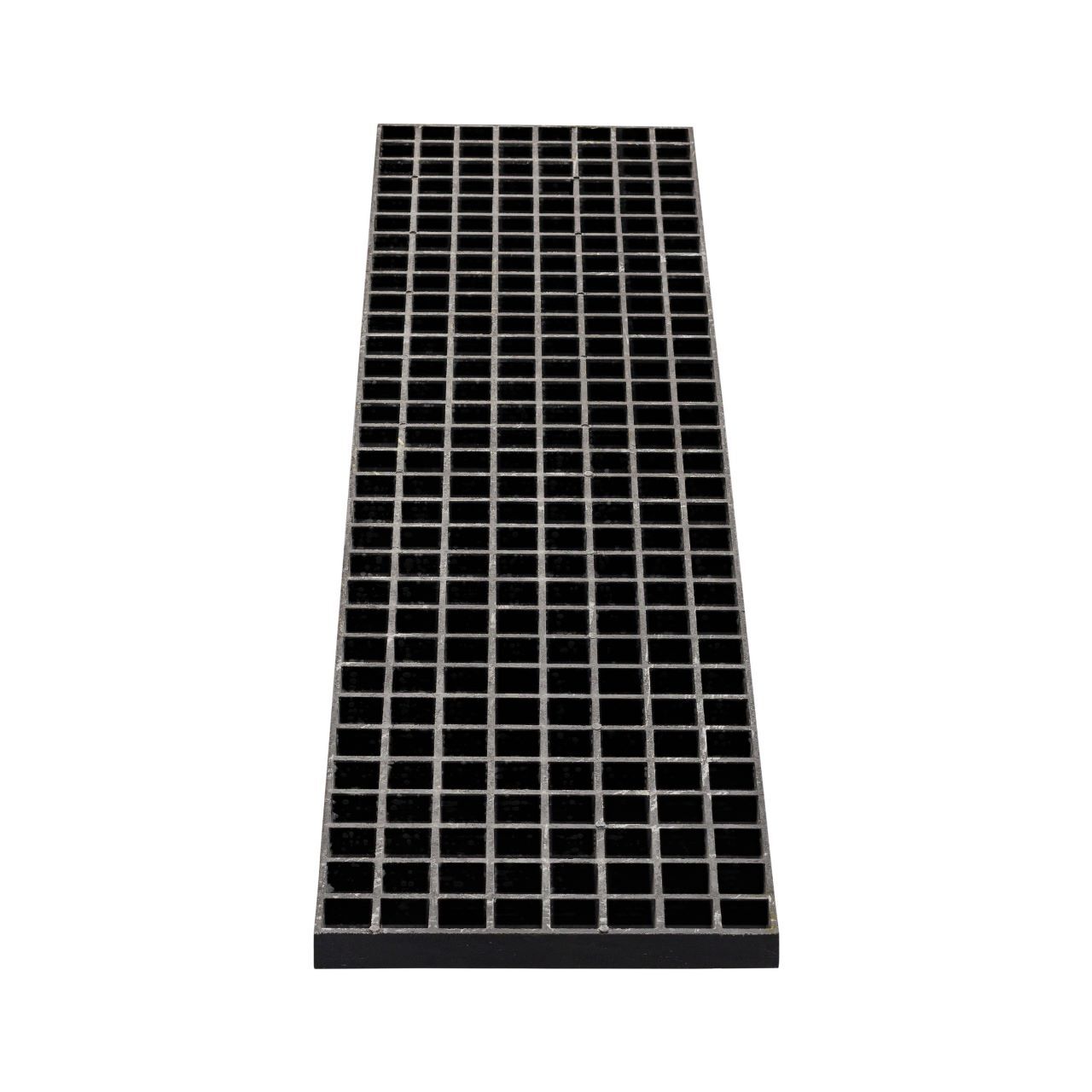

FRP Moulded Gratting

MOQ : 1 Number

FRP Moulded Gratting Specification

- Features

- Fire retardant, UV resistant, anti-slip, low maintenance

- Application

- Industrial floors, walkways, platforms, trench covers, marine decks

- Color

- Green, Yellow, Grey or as per requirements

- Material Grade

- ISO, ASTM, or as specified

- Thickness

- 25 mm, 38 mm, and others available

- Usage

- Drainage & Water Supply Work

- Installation Type

- Floor mounted, surface installed

- Form

- Moulded grating panel

- Load Capacity

- Designed for heavy, medium and light duty applications

- Product Type

- FRP Moulded Grating

- Main Material

- FRP

- Surface Treatment

- Anti-corrosive coated

- Weight

- Lightweight (varies with size and thickness)

- Feature

- Corrosion resistance, high strength-to-weight ratio

- Shape

- Rectangular/Square

FRP Moulded Gratting Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About FRP Moulded Gratting

FRP molded grating, also known as Fiberglass Reinforced Plastic grating, is a lightweight and durable grating solution used in various industrial, commercial, and residential applications. Made from a combination of fiberglass and resin, FRP molded gratings offer high strength, chemical resistance, and corrosion resistance, making them ideal for use in harsh environments, walkways, platforms, and other areas where a strong and anti-slip surface is required.

Frequently Asked Questions (FAQ) :

Q: What is FRP molded grating?

A: FRP molded grating is a type of grating made from fiberglass strands and resin that are molded together to form a strong and durable grid-like structure. This grating is widely used in different industries and settings for its high strength-to-weight ratio and corrosion-resistant properties.

Q: What are the advantages of using FRP molded grating?

A: FRP molded gratings offer several advantages, including high strength, lightweight, corrosion resistance, chemical resistance, low maintenance, anti-slip surface, and ease of installation.

Q: In which applications are FRP molded gratings commonly used?

A: FRP molded gratings are commonly used in industries such as chemical processing, water treatment, oil and gas, marine, and pulp and paper. They are also used in commercial settings like walkways, platforms, stair treads, and trenches, as well as in residential applications.

Q: Can FRP molded gratings withstand heavy loads?

A: Yes, FRP molded gratings are designed to withstand heavy loads and are engineered to meet specific load requirements depending on the application.

Outstanding Chemical & Temperature Resistance

This FRP moulded grating excels in aggressive industrial environments due to its exceptional resistance to acids, alkalis, and solvents. Capable of performing flawlessly between -40C and +180C, it offers reliability for applications ranging from chemical plants to marine decks. The anti-corrosive coating extends its service life well beyond two decades, ensuring reduced maintenance and long-term safety.

Versatile Design and Customization

Available in a range of mesh sizes such as 25x25 mm, 38x38 mm, and 40x40 mm, as well as diverse color options, the grating can be tailored to specific project requirements. It is supplied in standard and cut-to-size panels with thicknesses like 25 mm and 38 mm, supporting a variety of load capacities from light to heavy duty, perfect for industrial floors, walkways, and more.

FAQs of FRP Moulded Gratting:

Q: How is FRP Moulded Grating installed on industrial floors or platforms?

A: FRP Moulded Grating is typically floor mounted or surface installed using special clamps and fasteners. Its lightweight construction and deburred, smooth edges make handling safe and installation straightforward. The panels can be customized to fit trench sizes or specific layouts, ensuring secure and precise placement.Q: What benefits does FRP Moulded Grating offer over metal alternatives?

A: FRP Moulded Grating provides superior corrosion resistance, high strength-to-weight ratio, electrical insulating properties, and does not rust like metal grating. It is fire retardant, UV resistant, anti-slip, and requires much less maintenance, making it a cost-effective and safe choice for industrial applications.Q: When should I choose a specific mesh size or thickness for my application?

A: The choice of mesh size (25x25 mm, 38x38 mm, 40x40 mm) and thickness (such as 25 mm or 38 mm) depends on load requirements, open area needs, and intended use. Finer mesh is ideal for pedestrian walkways, while coarser mesh supports heavier traffic or drainage. Custom options can be provided to match project demands.Q: Where can FRP Moulded Grating be used effectively?

A: This grating is suitable for a wide range of environments, including drainage channels, water supply works, industrial walkways, platforms, trench covers, and marine decks. Its chemical and fire resistance also make it ideal for use in factories, treatment plants, and corrosive or hazardous areas.Q: What is the process for customizing FRP Moulded Grating panels?

A: Custom panels are fabricated based on client specifications, including shape, size, color, and thickness. After your requirements are submitted, the manufacturer prepares the moulded grating to precise dimensions and finishes edges smoothly. Additional surface treatments like anti-slip or anti-corrosive coatings are also applied as needed.Q: What standards and fire safety ratings does this grating meet?

A: FRP Moulded Grating meets industry-recognized EN, ASTM, and IS standards for quality and performance. It is rated self-extinguishing as per ASTM E84, providing safety assurance in environments with potential fire hazards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry